ABZ DesigNet vs Tahoe HYDROFLO For Designing Brine Fluid Conveyance

Table of Contents

A little background about two companies #

ABZ completed the development of the award winning “Crane Companion” in 1992. Building on that work, ABZ has continuously updated the program and now offers a complete fluid flow analysis program called “Design Flow Solutions” to its domestic and international customers.

HYDROFLO 3 is a powerful, yet easy to use Pump and Piping System Analysis software tool. Any type of incompressible liquid flow can be analyzed. Many types of conveyance systems can be modeled including open source/discharge, closed re-circulating and gravity flow systems. Industrial process, water supply, wastewater treatment, fire protection, sprinkler systems, chemical process, mine de-watering, swimming pool, pond/irrigation and HVAC systems can be quickly created, analyzed and solved for steady-state flows and pressures and operating parameters.

Our system #

Our brine conveyance system is something like this:

Requirement #

Two applications were utilized to model the piping & rate the pump that will provide adequate flow (user requirement). We have the provision to choose from among different impeller dia(s) for the pump but variable RPM isn’t an option!

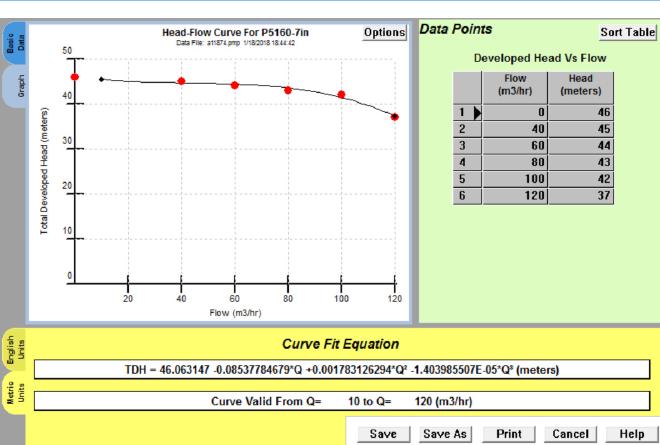

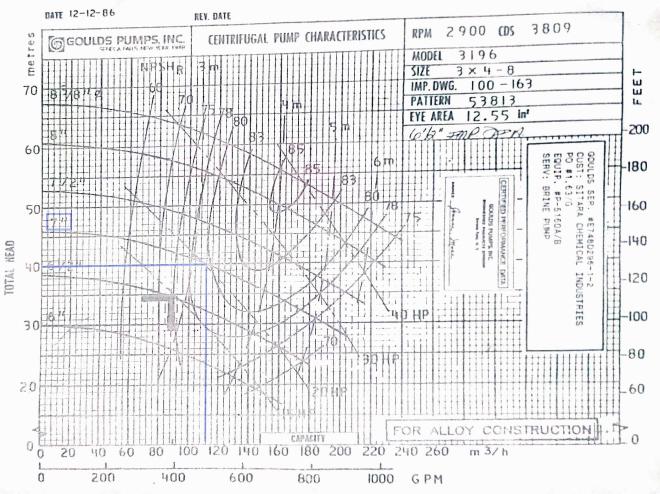

Manufacturer’s pump curve is used to provide multiple points of flow [Q] versus head [H] to model pumps curve mathematically, this approach is common to both applications. One can see its a polynomial data fitting of order 4 & the shut-off head (at zero flow) is also included as 46m

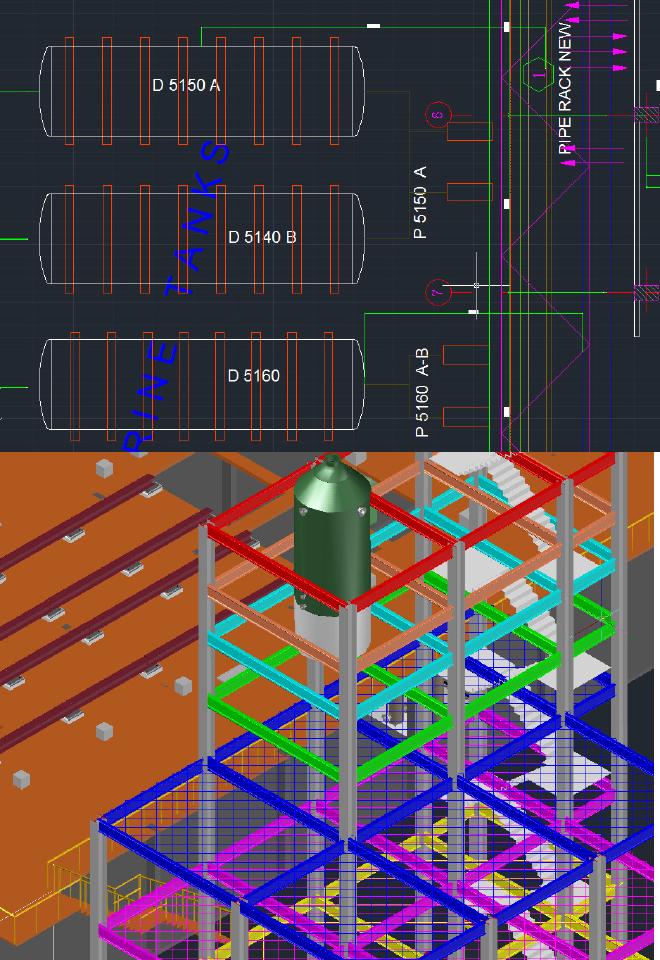

Plant layouts like the one shown above can effectively give us linear piping lengths as well as elevation plan. However, to determine actual quantity & type of fittings only an up-to-date P&ID will suffice. If you plan to use control valves & heat exchangers in your fluid conveyance system you further need equipment specs. In both applications for control valves you can given Cv or Kv values for other equipment you can either model them as fixed pressure drop devices or variable pressure drop devices. For the latter you need to have a curve or mathematical relationship for increasing pressure drop with increasing flow [Q]

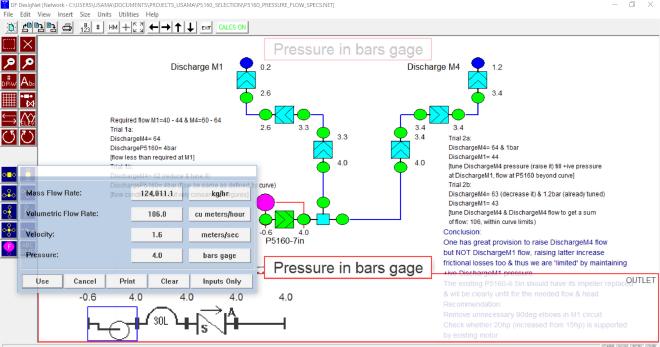

In the diagram below whole of the piping networks including the elbows, elevations, piping lengths, NRVs… is designed in ABZ. Next for iterative optimization x4 tries were conducted until a suitable convergence is achieved. ABZ programs works on the minimum degree of freedom principle (that automatically avoids over-specification of a problem), where user inputs minimum parameters at either inlet or exit nodes (shown in green) that can be solved to give a unique solution. In the last trial (2b) user requirements were met & the pump parameters were within manufacturer’s curve.

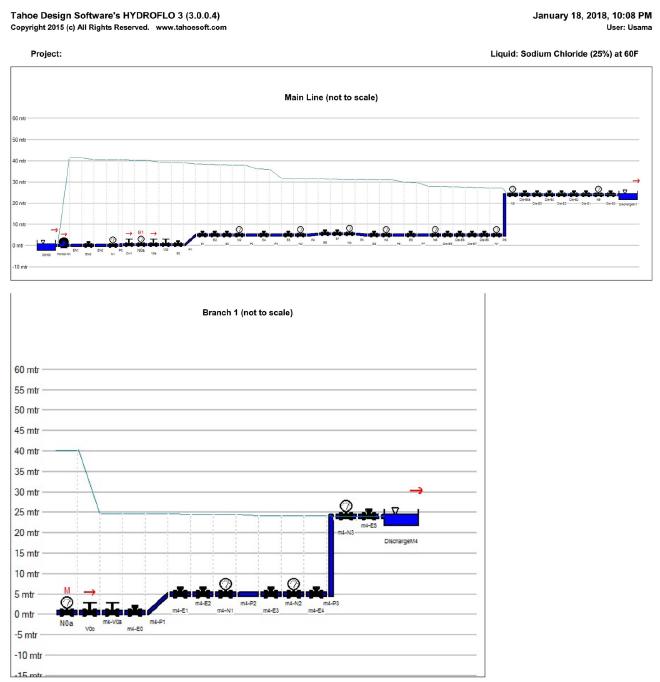

Similarly the problem was modeled in HYDROFLO as is shown below. One can see that the graphical interface is less cryptic that ABZ. Here instead of tees (for flow splitting) branch concept is introduced which is a highly valued feature. One can observe that though the elevations of both exits is same (24m) but the distance & the amount of fittings as well as pipe dia(s) are different. This is all hidden within the magenta blocks in ABZ & will be visible once the user clicks particular block.

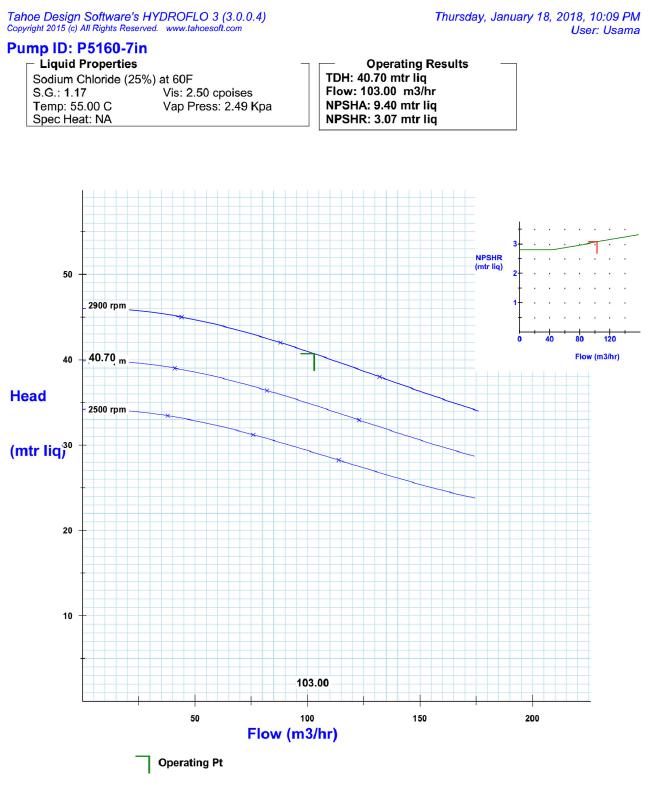

Calculations in HYDROFLO for pump selection is highly intuitive as user gets a much more convenient curve plot with the indicated operating point. This plot can further be extended for variable RPMs using Fan Laws.

Conclusions #

- Determining the direction of flow in both applications is ‘intelligent’ & is based upon system dynamic pressures & not by the user

- Operating point calculated by both application is highly similar. In ABZ it was 40 [H] versus 106 [Q] while in HYDROFLO it was 40.7 [H] & 103 [Q]. Compare these values to the manufacturer original curve shown above & I am happy to say that solutions do coincide greatly

- HYDROFLO also provided info about NPSHr because I chose to enter points for NPSHr as well; this feature is absent in ABZ

- Report utility in ABZ is highly comprehensive but only a PRO can read it! Customization are there to down strip it to a one page summary

- HYDROFLO although looks clean & user friendly but cannot handle compressible fluids while ABZ can (BIGGEST DOWNFALL I suppose!)

All of the project files & figures can be downloaded from this folder. The *.flo files are HYDROFLO while *.net are ABZ files. For ABZ two different approaches are used & they differ in the degree of freedom inputs I chose.