Defining Health Parameter for Air Compressors

Table of Contents

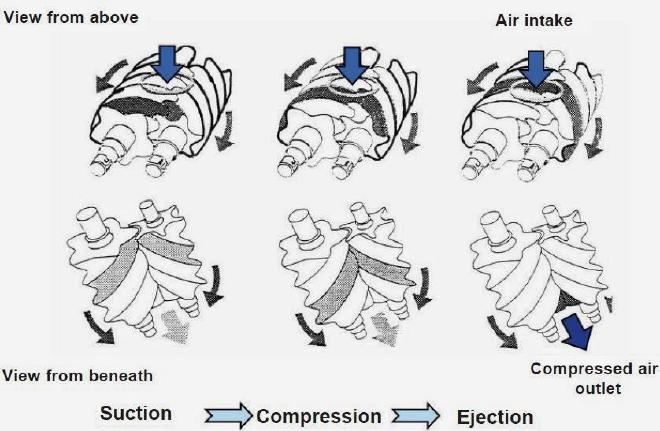

While maintaining air compressors (screw, positive displacement & centrifugal) in a process plant a general mathematical parameter quantifying its health is usually missing or is overlooked by process engineers. I being a regular practitioner of statistical process analysis ponder upon numerical figures to judge & classify asset degradation. To this end I required a computed efficiency that is a mathematical function of those parameters I have readily access to.

Calculating compressor efficiencies installed in process streams of petroleum gas is a different story altogether for it requires rigorous methods of calculating enthalpies via well known equations of state. What follows can be applied to air compressors generating essential utilities like Instrument air, Service air or hooked to some Pressure Swing Adsorption (PSA) unit…

Generating Methodology #

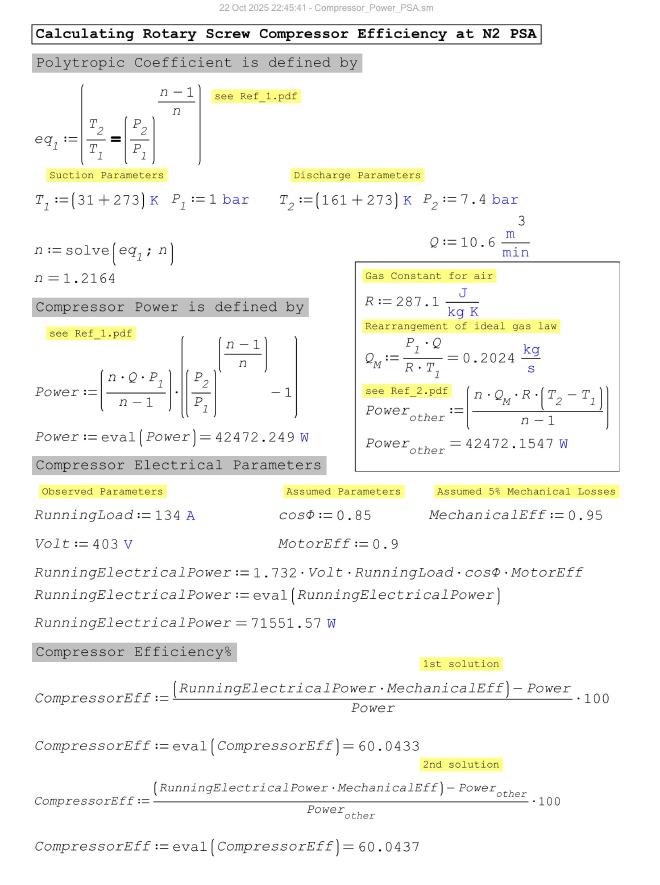

This calculation is a 5 step procedure

- Calculate polytropic coefficient n using suction/discharge Temperature & Pressure readings

- Calculate polytropic power for compressor using n & observed volumetric flowrate

- Calculate Electrical input power using observed motor parameters: Volts, Ampere, Power Factor, Motor Efficiency

- Assume (or ask the manufacturer) Mechanical power losses; usually between 3-5% or in other words a Mechanical Efficiency between 0.95-0.97

- Calculate running compressor efficiency

In a nutshell from process side you need logging of 5 parameters (suction/discharge Temperatures & Pressures plus the volumetric flowrate). From electrical side you need 4 parameters, the latter 2 (defined above) are conveniently written on motor’s specification plate. From mechanical side you need only 1 parameter or just assume it.

One thing I dislike is focusing upon my units while doing calculations (its just so irksome) & to aid me here is a free application from Russia SMath Studio. Its an alternative to commercial (& bloated) applications like Maple & MathCAD. Please download the portable & plugin ready version from here.

I will provide a manual calculation first so the equations used don’t appear cryptic to the reader. After getting the main gist the reader can adobt the ideas to a spreadsheet processor. Latter I will provide a Geogebra (v5) file which for readers will appear tad cryptic! This *.ggb file however can provide a glimpse for the correlations among various parameters & how effciency is effected. Again free & opensource you can download GeoGebra Classic 5 from here.

The equations used are taken from following references (notice the 2 versions of Power equations used) source 1 source 2

Simulating established model #

Utilizing the same mathematical steps as above I want to realize the effect of discharge temperature upon Compressor Power requirement as well as its Efficiency. Discharge temperature parameter is the sole parameter that will be effected by things other than compressor itself. For instance a bad air cooler, under-performing cooling tower, poorly designed exhaust duct …For this Geogebra is my favorite tool as it not only calculates the functions symbolically but is able to display the mathematical beauty expressed therein.

For the above temperatures are in Kelvin (K) displayed at x-axis, while Power (kW) & Efficiency are on y-axis

First thing I observed was the linear relationship exhibited between compressor power & discharge temperature while the relationship between Efficiency & discharge temperature had the best fit through a 2nd-degree polynomial in the said temperature range. Also one can infer (as common sense did dictate) that increasing discharge temperature is a bad omen for compressor’s health. User can also modify the “construction steps” of the *.ggb file to visualize similarly the effect of increasing discharge pressure. The latter is important because new screw compressors provides freedom of set point for discharge pressure¹. Statistically one can identify the minimum set point (& maximum efficiency discharge temperature allows) without sacrificing throughput needs.

All the files generated *.sm *.ggb *.pdf (converted reference webpages) are uploaded here for users to download & modify according to their needs